Breakthrough the bottleneck in the engineering chemical fiber industry and seize the opportunity of wearable intelligent products

In today's world, the century long changes are accelerating, and a new round of technological revolution and industrial transformation is profoundly reshaping the global order and development pattern.

The formation and development of new quality productivity will provide important support for all industries in China to comply with the trend of this round of scientific and technological revolution and industrial reform, and promote Chinese path to modernization with high-quality development. Duan Xiaoping, Vice President of the China Textile Industry Federation, stated that the development of new quality productivity in the chemical fiber industry requires attention to increasing variety, improving quality, and creating brands. This is an inevitable choice as the development of China's chemical fiber industry has entered a new stage of diminishing marginal benefits; Secondly, we should attach importance to fundamental innovation, promote the spirit of craftsmanship, encourage the industry and academia to strengthen innovative thinking, exchange and cooperation, and drive technological progress in the industry; The third is to break through the bottleneck project of the chemical fiber industry chain, by further exploring and overcoming the bottlenecks and pain points in the industry chain, grasping the initiative of industrial safety development, and enhancing industrial competitiveness; The fourth is to embrace intelligent manufacturing and green manufacturing, seize the opportunity of the fourth industrial revolution led by intelligent manufacturing and AI, and grasp the three key points of green manufacturing in the industry, namely new energy-saving and emission reduction technologies, green products such as bio based and recycling, and actively adopt energy storage and green power technologies.

Extending new spaces with new materials

To develop new quality productivity, we need to extend new space with new materials. The successful development of various new materials has changed the structure of yarns, leveraged the development and innovation of their properties, and enabled textiles to be widely used in fields such as smart wearables, biomedicine, aerospace, etc., meeting major national needs.

Xia Zhigang, Vice Dean of the School of Textile Science and Engineering at Wuhan Textile University, stated that in recent years, the development of the chemical fiber industry has greatly promoted the technological progress and innovation of spinning and yarn products. High strength, high modulus, and high-performance fibers such as meta aramid, polyimide, and polyarylester have promoted the progress and innovation of ring spinning technology.

The Wuhan Textile University team has therefore innovatively invented a method of thermal field layering softening and aggregation control fibers for smooth and polished spinning, breaking through technical bottlenecks and solving the technical problem of high-performance fibers such as aramid not being able to produce high-quality yarn. They have also overcome the technical contradiction between the softness and comfort of yarns and fabrics and the inability to simultaneously improve high strength, smoothness, and wear resistance. At the same time, chemical filament raw materials such as drawn yarn, false twist deformed yarn, and air deformed yarn have promoted the progress and innovation of ring spinning composite spinning technology, solving the two major technical bottlenecks of core wrapping and wrapping composite spinning.

In the view of Professor Chen Ye from Donghua University, the new quality productivity of fiber materials should adapt to the needs of human beings, ecological environment, and emerging industries. For example, in terms of raw material empowerment, genetic engineering, synthetic biology, and material genetic engineering should be used to lead the innovation of fiber material development models, develop bio based materials, biodegradable materials, fibers, and attach importance to the use of chemical transformation and regeneration technologies and environmentally friendly production materials; In terms of manufacturing innovation, attention should be paid to technological restructuring, process optimization, the development of efficient, flexible, and digital processing technologies, the integration of energy and resources, and the establishment of low-carbon technology integrated factories; In terms of product reshaping, we need to break through the limits of fiber fineness, strength, functionality, intelligence, etc., research the coloring and discoloration of raw materials, design technologies for product recyclability, and achieve sustainable development of the entire industry chain including raw material sources, technical systems, production processes, and product applications.

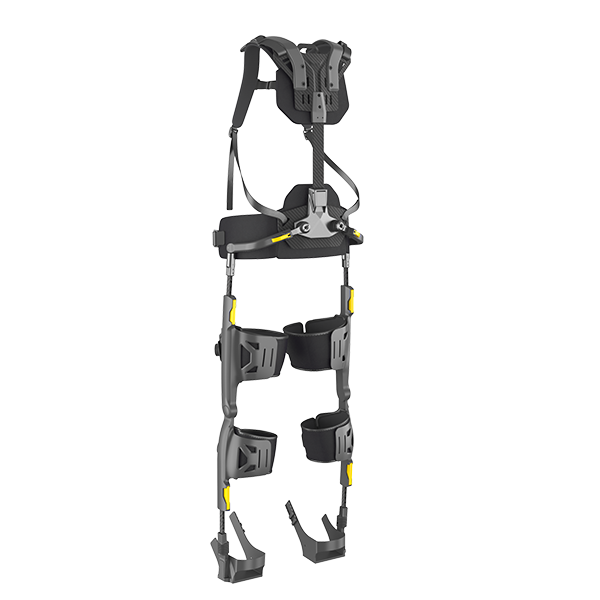

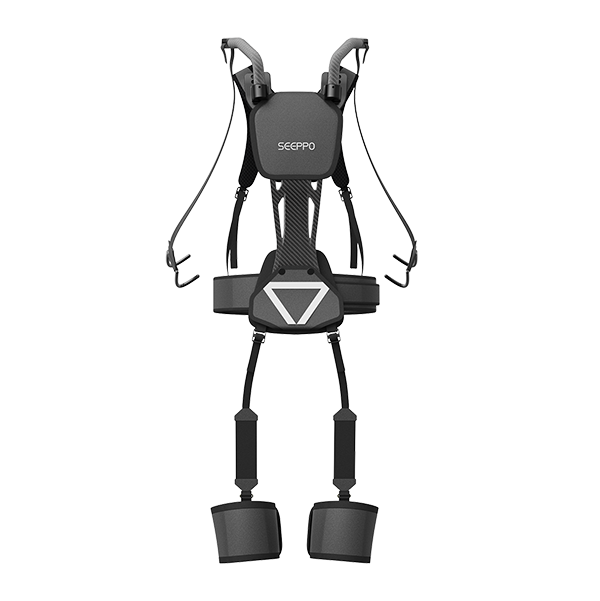

Seize the opportunity of wearable smart textiles

With the rapid development of smart terminals and the Internet of Things, smart wearable devices have become one of the research hotspots at home and abroad. Professor Wang Rui from Beijing Institute of Fashion Technology pointed out that in recent years, various intelligent wearable devices have emerged in large numbers, which can be described as "from head to toe", such as intelligent sportswear and accessories, clothing heating systems, luminous clothing, LED display smart shirts and solar textiles, music jackets, invisibility jackets, etc. Traditional smart clothing is a combination of clothing and traditional semiconductor devices. However, currently, some smart materials and devices have been used in smart clothing, and many products have been developed, such as smart sportswear, charging boots, satellite navigation shoes, medical tight fitting clothes, solar bikinis, etc.

Xi'an University of Technology has made many explorations in the field of smart wearables. Fan Wei, Vice Dean of the School of Textile Science and Engineering at Xi'an Engineering University, introduced the preparation of Janus graphene PBO fabric based flexible electronic devices and their application in the field of intelligent fire protection. He stated that the preparation method of the electronic device is simple and efficient, the process is short, and it can be mass-produced. It has excellent conductivity, flame retardancy, high temperature resistance, thermal protection, and wearability. The firefighting suit can be used for human movement monitoring and gas detection. The intelligent firefighting mask has excellent breathability and filtering properties, and can indirectly reflect the health status of firefighters through respiratory signal monitoring, providing effective safety protection and health warnings for firefighters.

In the future, smart clothing will combine big data and mobile healthcare. Through front-end signal acquisition and display collection, signals will be transmitted to the cloud through signal transmission terminals such as mobile phone Bluetooth, wireless networks, etc., and then analyzed and processed for feedback, enabling online diagnosis, three-dimensional physiological index monitoring, etc. As the terminal carrier of mobile healthcare, wearable smart materials and devices, especially wearable smart devices that can detect human physiological indicators, will have an increasing market share in the wearable market in the future, "said Wang Rui.

Xia Zhigang stated that "carbon peak" and "carbon neutrality" are global development trends, and the future textile industry will be a "technology, fashion, and green" industry. He hopes that the industry can develop more wearable smart textiles through fiber raw materials, spinning technology, and other improvements to meet the needs of consumers.

Targeting the sustainable development track

Chemical fibers have high production and wide applications, and their environmental friendliness and sustainability are of great significance to the development of China's textile industry.

In recent years, Hengyi Petrochemical Co., Ltd. has made significant progress in promoting the green development and environmental protection of the polyester industry through the research and development of raw liquid colored fibers, antimony free polyester and titanium based catalysts, efficient textile recycling technology, and biodegradable polyester. Wang Songlin, Executive Vice President of Hengyi Petrochemical and Dean of Hengyi Research Institute, introduced that Hengyi Research Institute has been researching biodegradable copolyester fibers based on PET since 2019. Through intrinsic chemical molecular structure adjustment, some mechanical properties are sacrificed in exchange for full biodegradation. The product's degradability is 3-16 times higher than PET fibers, and the authoritative institution's composting degradation rate test reached 72% in 90 days.

In Wang Songlin's view, under the background of circular economy and dual carbon, there are two ultimate ways out for textiles: those that can be recycled should be recycled and reused as much as possible, and those that cannot be recycled should be biodegradable. The proportion of PET fibers in the chemical fiber industry exceeds 80%, solving the problem of biodegradability of PET fibers and basically solving the environmental friendliness of textiles. He suggested that the next step for biodegradable polyester should be towards green, bulk, and standardized development. The production process should use new ecological catalysts, and all parties should work together to quickly introduce relevant product and testing standards.

As one of the leading enterprises in the chemical fiber industry, Taihe New Materials is also a leader in practicing green development. Song Xiquan, Secretary of the Party Committee and Chairman of Taihe New Materials, introduced that Taihe New Materials has launched internationally leading technologies such as ECODYTM green printing and dyeing, achieving a leap from following and running to leading.

Tangshan Sanyou Group Xingda Chemical Fiber Co., Ltd. has always regarded sustainable development as the lifeline of the enterprise and actively explored low-carbon and green development paths. Zhang Dongbin, Executive Vice General Manager of Sanyou Chemical Fiber, stated that in order to explore the sustainable development path of the regenerated cellulose fiber industry, Sanyou Chemical Fiber has jointly initiated the establishment of the Green Development Alliance for the regenerated cellulose fiber industry with multiple enterprises and associations; Actively cooperate with Canopy to achieve a button count of 31.5 by 2023, achieving a deep green shirt rating (button ranking report is the primary tool used by brands to evaluate the supply chain of synthetic cellulose fibers and identify which manufacturers can better meet Canopy Style's commitments. It is a proprietary term); Being the first in the industry to obtain FSC Forest Chain of Custody certification, ensuring the use of sustainable forest resources.

Strengthen the development of high-end products

Aramid, along with carbon fiber and ultra-high molecular weight polyethylene fiber, is known as one of the world's three high-performance fibers, characterized by low relative density, high strength, high modulus, high temperature resistance, corrosion resistance, and good insulation properties. According to Lv Jiping, Deputy General Manager of Taihe New Materials' Aramid Division, the global annual production capacity of meta aramid is currently 55500 tons. The main production enterprises include DuPont from the United States (22000 tons), Taihe New Materials from China (16000 tons) and Supermex from China (5000 tons), and Teijin from Japan (4500 tons). It is mainly used in industrial filtration, safety protection, and aramid paper fields, with usage proportions of 31%, 27%, and 31%, respectively.

The global annual production capacity of para aramid is 110000 tons, with major production companies including Teijin from Japan (36000 tons), DuPont from the United States (28000 tons), as well as Taihe New Materials from China (16000 tons) and Cologne from South Korea (15000 tons). It is mainly used in safety protection, friction sealing, rubber reinforcement, and fiber optic cable fields, with application proportions of 41%, 19%, 18%, and 15%, respectively.

Lv Jiping pointed out that in the future, the development of high-performance aramid products will be the main trend in the domestic aramid industry. China aims to strengthen and expand the upstream and downstream industrial chains of high-performance fibers such as aramid, and achieve scale and low cost through industrial chain layout and engineering integration. At the same time, industries and enterprises should strengthen the development of high-strength, high modulus, differentiated, and functionalized aramid products to increase their added value. In addition, the aramid industry also needs to promote green development, such as achieving aramid recycling and reuse.

With the continuous improvement of people's quality of life, the demand for high-end materials such as functional nylon is also growing. Chen Jizong, Senior Engineer of the Technology Development Department of Guangdong Hengshen Meda New Materials Co., Ltd., mentioned that since 2013, the demand for caprolactam (CPL) in China has grown rapidly, and the production capacity has achieved self-sufficiency; The demand for slicing and production have both steadily increased; The demand and production capacity of nylon continue to grow, with a relative decrease in costs and an increase in market share in synthetic fibers, resulting in a relatively stable supply-demand gap; CPL、 The integration of polymerization and spinning has become a development trend in the industry.

However, Chen Jizong also mentioned that although nylon equipment, technological advancements, and the evolution of new products have driven the rapid development of the industry, the industry still faces many practical challenges. In response, Chen Jizong suggested that industry enterprises should make changes in high-end, green, intelligent, collaborative, branding and other aspects. (Reporter Ma Yan)

Translated from: China Industry News